Laina Hana Hana ʻAila Custard

Laina Hana Hana ʻAila Custard

Laina Hana Hana ʻAila Custard

Wikiō Hana:https://www.youtube.com/watch?v=AkAcycJx0pI

Alaina hana mea ʻono custardpili i kahi moʻo o nā kaʻina hana automated a me semi-automated e hana i ka mea ʻono custard me ka maikaʻi, kūlike, a me ka maʻemaʻe. Aia ma lalo kahi wehewehe kikoʻī o nā pae maʻamau i kahi laina hana mea ʻono custard:

1. Ka lawelawe ʻana a me ka hoʻomākaukau ʻana i nā mea hoʻohui

- Ka Hoʻokipa a me ka Mālama ʻana i ka Waiū

- Loaʻa ka waiū maka, hoʻāʻo ʻia no ka maikaʻi, a mālama ʻia i loko o nā silos i hoʻopaʻa ʻia.

- Koho ʻē aʻe: Pauka waiū i hoʻohui hou ʻia + wai (no ka lōʻihi o ke ola mālama).

- Ka lawelawe ʻana i ke kōpaʻa a me ka mea ʻono

- Ua kaupaona ʻia ke kōpaʻa, ka syrup kulina, a i ʻole nā mea ʻono ʻē aʻe a ua hoʻoheheʻe ʻia.

- Ka Hana ʻana i ka Pauka Hua Manu a me ka Hua Manu

- Ua hui pū ʻia nā hua wai (pasteurized) a i ʻole ka pauka hua manu me ka wai.

- Mānoanoa a me nā mea hoʻopaʻa

- Ua kāwili mua ʻia ka palaoa kulina, ka palaoa i hoʻololi ʻia, a i ʻole nā mea hoʻomānoanoa (e like me ka carrageenan) e pale aku i ka ʻūlū ʻana.

- Nā mea ʻono a me nā mea hoʻohui

- Hoʻomākaukau ʻia ʻo Vanilla, caramel, a i ʻole nā mea ʻono ʻē aʻe, me nā mea hoʻomalu (inā pono).

2. Hoʻohuihui & Hoʻohuihui

- Hoʻohuihui Pūʻulu a Hoʻomau paha

- Hoʻohui ʻia nā mea hoʻohui i loko o kahimīkini kāwili ʻoki kiʻekiʻea i ʻolepahu hoʻohuihui muama lalo o nā mahana i kāohi ʻia (e pale aku i ka mānoanoa ʻana ma mua o ka manawa).

- Hiki ke hoʻopili ʻia ka homogenization no kahi ʻano laumania.

3. Kuke ʻana a me ka Pasteurization

- Kuke Hoʻomau (Mea Hoʻololi Wela ʻIli i ʻoki ʻia)

- Hoʻomehana ʻia ka hui ʻana i75–85°C (167–185°F)e hoʻoulu i ka gelatinization starch a hoʻomānoanoa i ka mea ʻono.

- Pasteurization (HTST a i ʻole Batch)

- Manawa Pōkole Mahana Kiʻekiʻe (HTST) ma72°C (161°F) no 15-20 kekonaa i ʻole ka pasteurization batch e hōʻoia i ka palekana microbial.

- Pae Hoʻoluʻolu

- Hoʻomaʻalili wikiwiki i4–10°C (39–50°F)e ho'ōki i ka kuke hou ʻana a mālama i ke ʻano.

4. Hoʻohui like ʻana (Koho)

- Homogenizer Kaomi Kiʻekiʻe

- Hoʻohana ʻia no ka ʻano laumania loa (kāohi i ka graininess).

5. Hoʻopiha a me ka hoʻopili ʻana

- Nā Mīkini Hoʻopiha Akomi

- Hoʻopiha ʻeke(no ke kūʻai liʻiliʻi) a i ʻolehoʻopiha nui(no ka lawelawe meaʻai).

- Hoʻopiha Aseptic(no ke ola lōʻihi) a i ʻolehoʻopiha wela(no ka mālama ʻana i nā mea a puni).

- Nā ʻAno Hoʻopili:

- Nā ʻōmole palakiko, nā pahu pepa, nā ʻeke, a i ʻole nā kini.

- Hiki ke hoʻohana ʻia ka hoʻoheheʻe ʻana o ka nitrogen e hoʻolōʻihi i ke ola o ka waihona.

6. Hoʻoluʻolu a me ka mālama ʻana

- Hoʻolulu pahū (inā pono)

- No ka custard i hoʻomaʻalili ʻia, hoʻomaʻalili wikiwiki i4°C (39°F).

- Ka Waihona Anu

- Mālama ʻia ma4°C (39°F)no ka custard hou a i ʻole ka ambient no nā huahana i mālama ʻia me UHT.

7. Ka Mana Hoʻomalu a me ka Hoʻāʻo ʻana i ka maikaʻi

- Nā Nānā ʻana i ka Viscosity(me ka hoʻohana ʻana i nā viscometers).

- Ka Nānā ʻana i ka pH(pahuhopu: ~6.0–6.5).

- Hoʻāʻo Microbiological(ka helu holoʻokoʻa o ka pā, ka hū/ʻōpala).

- Loiloi Sensory(ʻono, ʻano, waihoʻoluʻu).

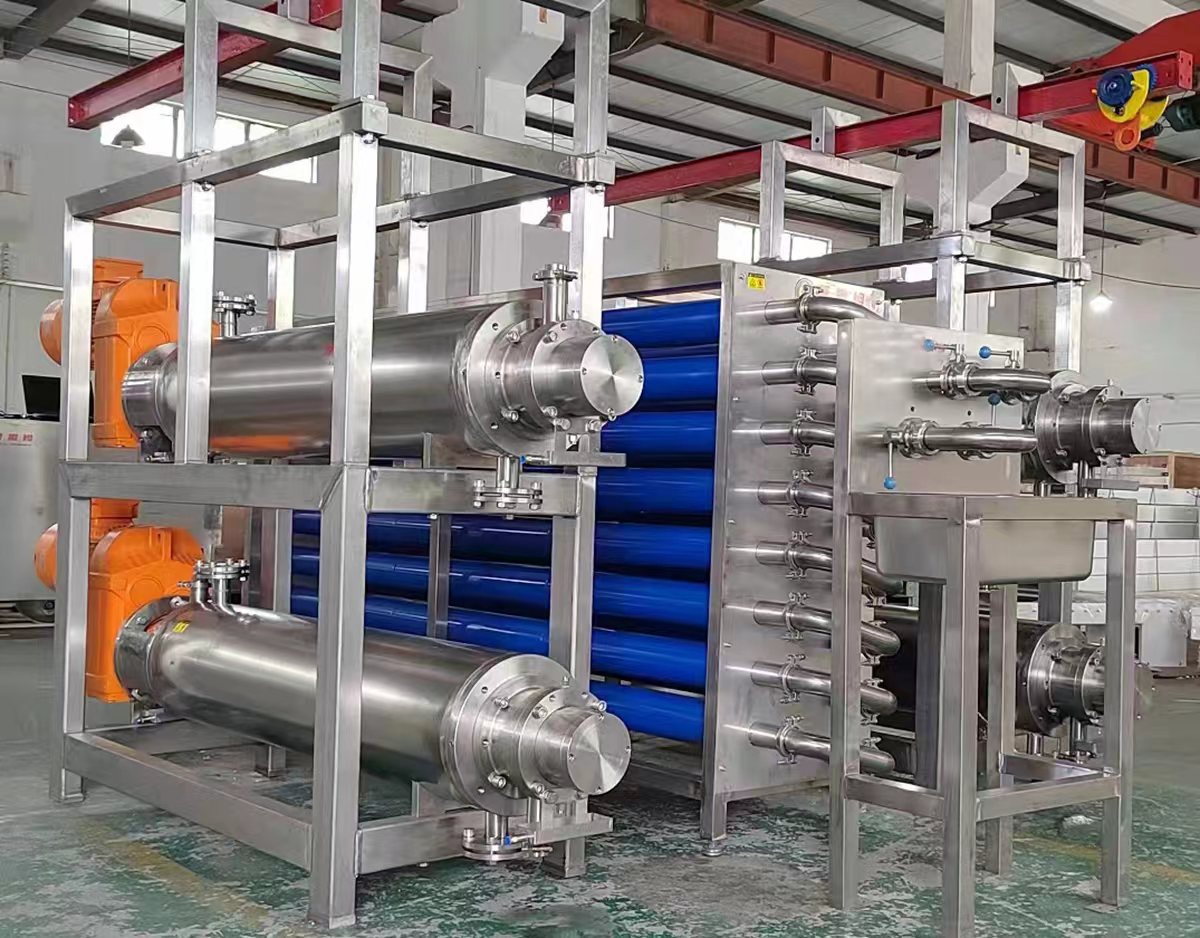

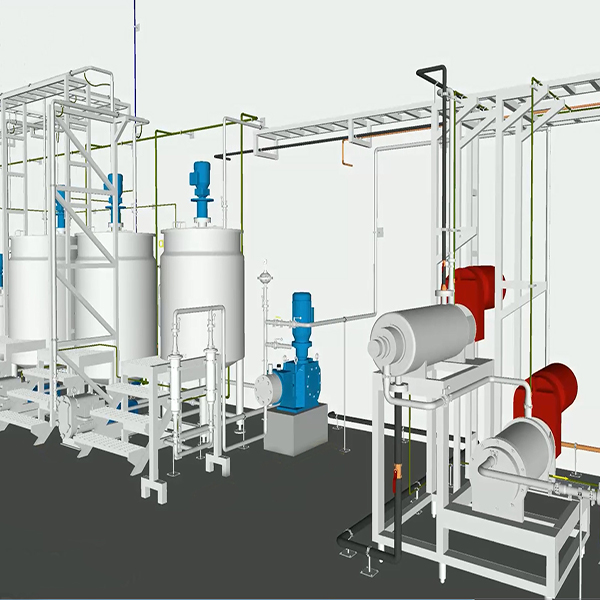

Nā Lako Koʻikoʻi ma ka Laina Hana Hana ʻAila Custard

- Nā Pahu Mālama(no ka waiū, nā mea hoʻohui wai).

- Nā ʻōnaehana kaupaona a me ka ana ʻana.

- Nā Mixers Kiʻekiʻe-Shear a me nā Pahu Premix.

- Mea hoʻomaʻemaʻe (HTST a i ʻole Batch).

- Mea Hoʻololi Wela ʻIli i ʻoki ʻia (no ka kuke ʻana).

- Mea Homogenizer (koho).

- Nā Mīkini Hoʻopiha (piston, volumetric, a i ʻole aseptic).

- Nā Tunnels Hoʻoluʻolu.

- Nā Mīkini Hoʻopili (sila ʻana, lepili ʻana).

Nā ʻano o ka Custard Sauce i hana ʻia

- Custard i hoʻopaʻa ʻia i loko o ka pahu hau(pōkole ke ola papa, ʻono hou).

- Kaleka UHT(ola lōʻihi, sterilized).

- Hui Custard Pauka(no ke kūkulu hou ʻana).

Hana Hoʻokele Hana ʻAkomi a me ka Pono

- Nā ʻōnaehana hoʻokele PLCno ka mālama pono ʻana i ka mahana a me ke kāwili ʻana.

- Nā ʻōnaehana CIP (Hoʻomaʻemaʻe-ma-kahi)no ka hoʻomaʻemaʻe.

Ke Kauoha ʻana i kahi kahua

E kākau i kāu leka ma aneʻi a hoʻouna mai iā mākou